Product inspection

Fail/pass verification

Picking and place

Universal Robots UR5e

Schunk gripper

Zivid One+ Small 3D camera

Company

MoviMED

Location

USA

Application

Product inspection

Picking automation

Features

Fail/Pass verification

Universal Robots UR5e

Schunk gripper

Hi-resolution 3D camera

3D camera

Zivid One+

Published

5 May 2020

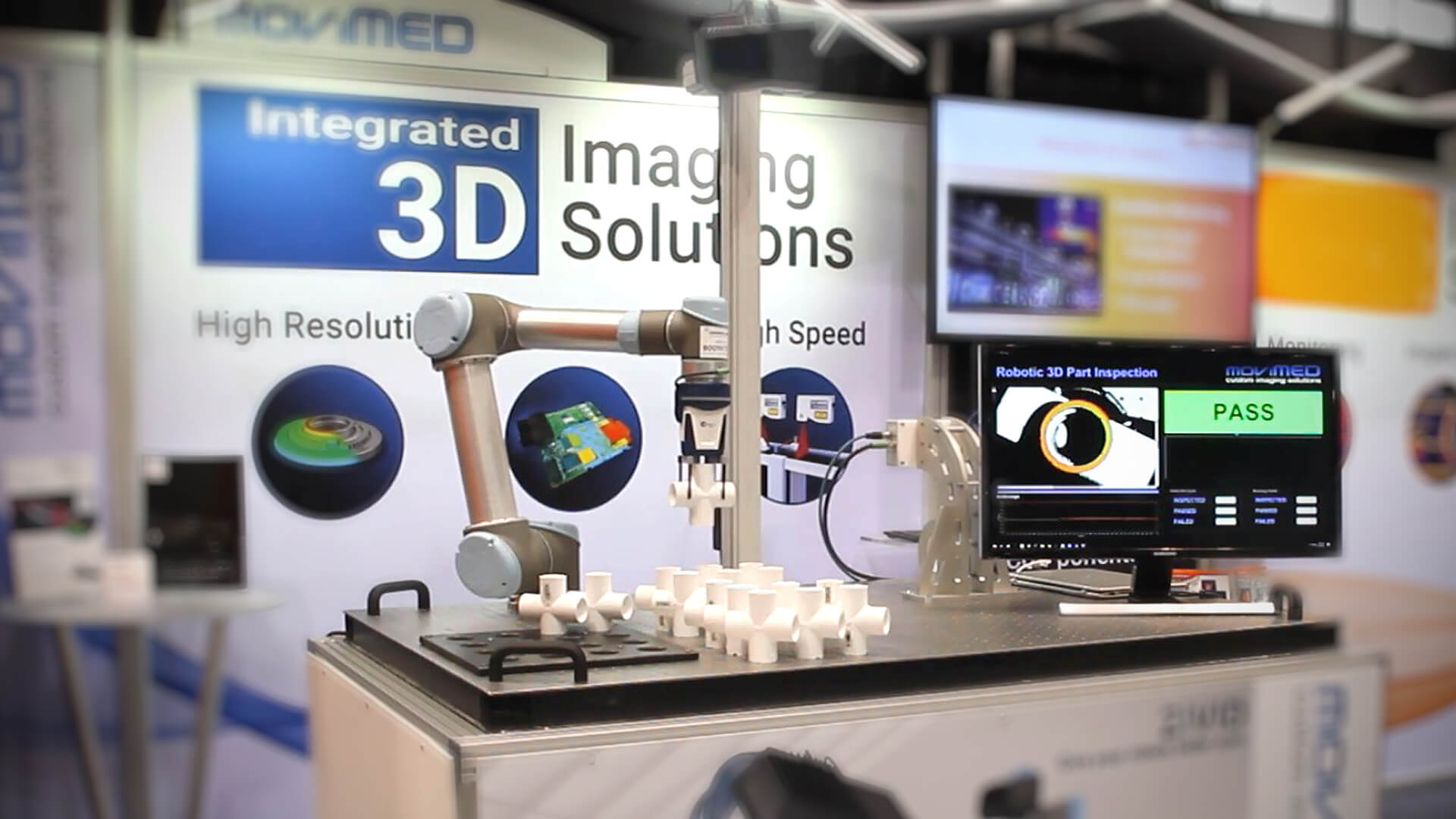

Demonstrate the latest thinking in machine vision-led cobot technology, in a confined public space, and on a very short lead time… MoviMED turned to the Zivid One+ 3D color camera in a quality inspection role to demonstrate its full range of capabilities.

Recognised as one of North America’s go-to providers of machine vision-led automation solutions, MoviMED is an expert in 3D imaging applications. Its capabilities cover the complete range of camera technologies, including laser triangulation, stereoscopic scanning, time of flight and structured light.

The company’s name, an acronym of the words motion, vision and medical, hints at its origins as a company focused on medical imaging. Established in 1999, MoviMED was initially developing scientific imaging systems for such applications as point of care testing, rapid infectious disease testing, DNA research and rapid drug discovery.

Based in Irvine, California, MoviMED today addresses a much broader range of industrial sectors, providing high-end, high-resolution and high-speed line scan, 2D and 3D imaging solutions. As both system integrator and distributor, the company offers cameras and sensors, technical consulting and support.

The company is a regular exhibitor at Automate, North America’s biggest automation solutions exhibition. Showcasing the latest in cutting-edge robotics, vision and motion control technology, this global event is well regarded for its live demonstrations by the world’s leading system integrators.

In choosing an application to demonstrate live at the 2019 Automate exhibition in Chicago, MoviMED wanted to identify a real world challenge that would not only demonstrate the latest thinking in machine vision but which would also be of relevance to as wide a possible cross section of industry.

One real-world application area in particular that often presents itself to MoviMED is that of ‘assisted inspection’, whereby a part that has traditionally required an operative to perform a quick visual inspection can be done more efficiently and reliably by a small collaborative robot or cobot working in the same physical space or less. This became the starting point.

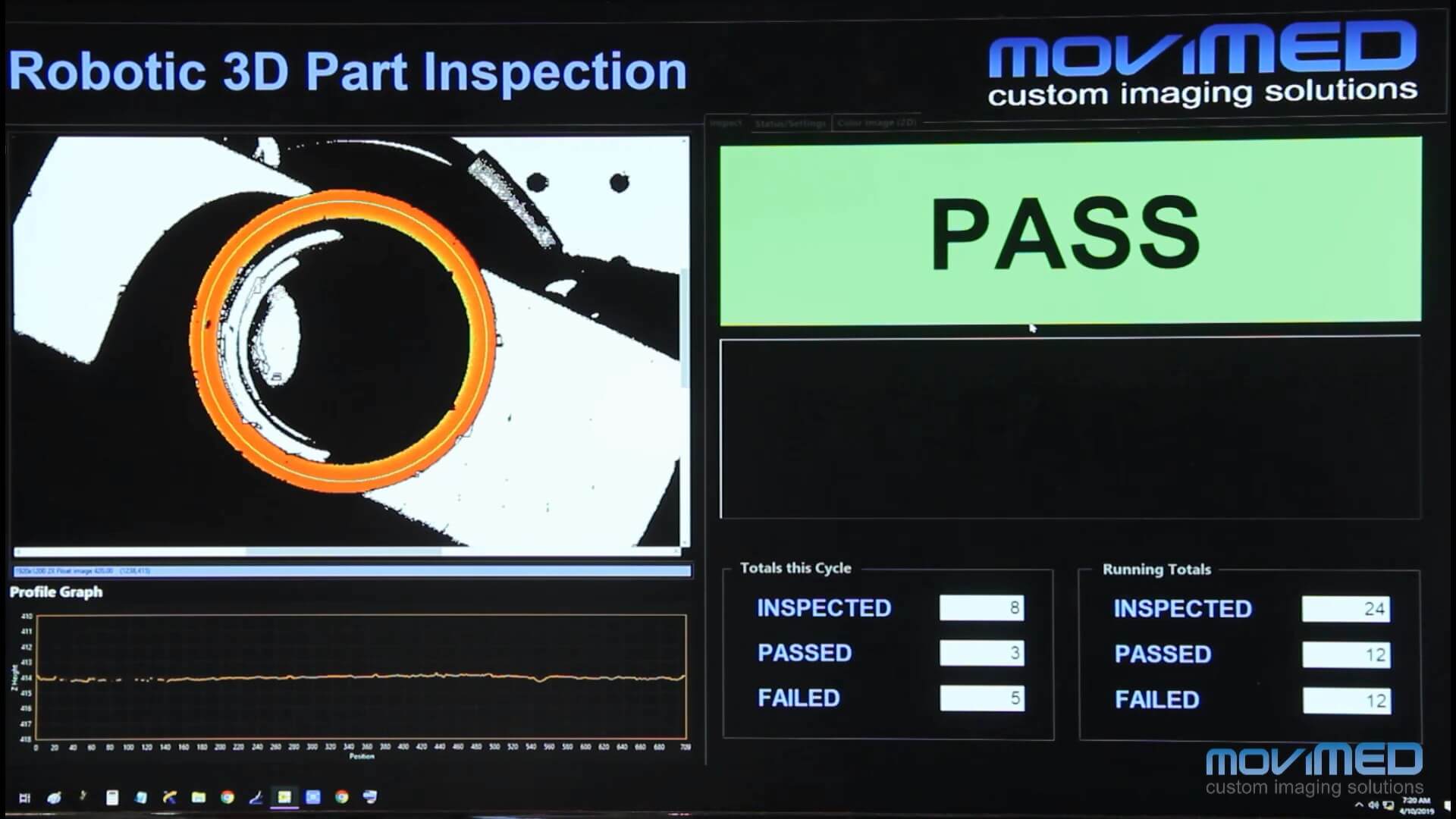

As the target object to be machine vision inspected, MoviMED decided then to go for a regular 90º equal tee PVC pipe fitting. A robotic arm would pick-up the fitting, present an open end to a static 3D camera for visual inspection and depending on the result, would place it in corresponding pass or fail locations.

Markus Tarin

President and CEO, MoviMED

In choosing a 3D machine vision camera technology to apply to the tee pipe fitting inspection problem, a key selection criteria was image resolution. A wide spread of flaws were to be introduced into the fitting ends, and all flaws needed to be identified, however perceptible or imperceptible in nature.

As in the real-world application, the tee pipe fitting flaws spanned from more obvious indentations and plastic flashing to far less visible scratches and minor deformations to the rim. This aimed to mirror a realistic inspection requirement where a variety of different flaws needed detection to ultimately assure plumbing system integrity.

President and CEO of MoviMED, Markus Tarin commented, “A PVC pipe fitting is quite indicative of a range of injection moulded plastic parts that require a visual quality check prior to packaging and dispatch. Minor product flaws can occur, and they do need reliable identification. In the case of a pipe fitting of course it’s more essential, since flaws can cause blockages and a poor seal, resulting in leaks.”

The choice of 3D camera technology was also influenced by the simple fact that both camera and target object were going to be static at the point of inspection. At the same time, the pipe fitting’s small diameter and wall thickness, 33.4 mm and 3.38 mm respectively, defined the need for a relatively tight field of view, as Tarin explained:

What we are always trying to do is achieve the highest possible level of fidelity in our 3D imaging. It makes little sense using a camera with a field of view that much greater than the target object, when in effect all you’re doing is capturing and processing irrelevant data and effectively wasting resolution.

Taking into account the application’s resolution and field of view requirements and the static nature of the inspection process, MoviMED ruled out laser triangulation, stereoscopic and time of flight 3D camera technologies, favouring instead a structured light solution.

The camera they selected for the application was the Zivid One+ Small full-color 3D camera. Based on a structured light measurement technique, it provided the performance needed to identify even the smallest flaw in the white PVC tee pipe fitting.

The camera’s general specifications are as follows:

As a National Instruments Alliance Silver Partner with Vision Specialty, MoviMED then used the LabVIEW systems engineering software to develop custom 3D pipe inspection and pass/fail algorithms and to implement 3D camera and robot arm control. The Zivid software development kit was used to create a custom camera interface for the LabVIEW application.

The robot arm chosen for the application was Universal Robots’ UR5e, an adaptable, lightweight collaborative industrial robot for tackling medium duty applications. The technical characteristics of the robot arm were more than sufficient for pipe fitting handling in the confined exhibition booth space, and are listed as follows:

For the robot gripper MoviMED chose to use a Schunk fully electrically controlled gripper, specifically designed for cobots with tactile force feedback to avoid deformation of the pipe fitting. Custom gripper attachments were 3D printed, having a half-moon shape and foam inserts for extending deep into the pipe radius.

In order to simplify application software development, the pipe fittings for inspection were delivered from defined tray positions at a fixed location. After robot picking, and subsequent visual inspection by the 3D camera, good parts were placed in pre-determined positions on the bench alongside, while bad parts were dropped in a bin.

Integration of the Zivid One+ Small 3D color camera, UR5 cobot and Schunk gripper, using the LabVIEW software development environment, created an ultra-reliable and highly efficient means of inspecting PVC tee pipe fittings.

The camera’s high-definition point-cloud imaging combined with custom software algorithms ensures even the most minor product flaws are detected, while the robot arm and gripper combination made for fast and safe part handling in a confined table-top space.

From conception and equipment sourcing to testing and final commissioning on site, the complete automation project took just two weeks to complete and was warmly received by attendees at the Automate exhibition. And it was the first time MoviMED had integrated the Zivid camera with the UR5.

Tarin said, “Achieving 99.9%+ accuracy in any kind of automated inspection process is a challenge for any machine vision developer, you pick your technology and you go all out to maximise its performance. In this simple application, I think we demonstrate quite clearly what can be achieved once you’re able to capture the right 3D imaging resolution and have prepared the right inspection recipes. It’s a highly flexible solution – change the part to be inspected, change the inspection recipe. It’s ideal in lower volume, high mix production scenarios.”

“Importantly, as a deliberately ubiquitous kind of application, I also believe it proves just how technically and financially accessible this kind of technology is to a much wider range of cobotic tasks; not only for quality inspection but in random bin-picking, pick-and-place and de-palletizing too.”

“Such a smart cobot cell doesn’t get fatigued or make mistakes and doesn’t need to take a break, it assists the workforce and takes care of those mundane tasks. Compared to larger autonomous industrial robot cells it really is at an entry-level price and irrespective of initial NREs, the ROI is that much higher.”

A further differentiating feature of the Zivid 3D camera is its high-contrast, full-color image capture capability and its inherent ability to tackle more problematic shiny metallic or dark, light-absorbing objects. While agreeing that the inspection of the white PVC pipe fittings didn’t call for such a capability, Tarin noted its potential.

“The ability to reliably differentiate parts purely on color, irrespective of ambient light conditions and the nature of the object surface, simply further expands the opportunities for cobot application. Even in this small demonstration, we could have been bin-picking different colors of pipe fittings and placing them in specific locations. It’s a further vector for the development of artificial intelligence – anything is possible.”

Our team of engineers can help with high-end, high-resolution and high-speed line scan, 2D and 3D imaging applications. We are known in the industry as the go-to company for machine vision, when everything else has failed.

Zivid brings

Gjerdrums

N-0484, Oslo

Norway